Asme section viii hydrostatic test pressure gauge 03 21 2013 10 08 am what we do offshore is we have a class 0 05 pressure calibrator which is calibrated yearly by a certified company.

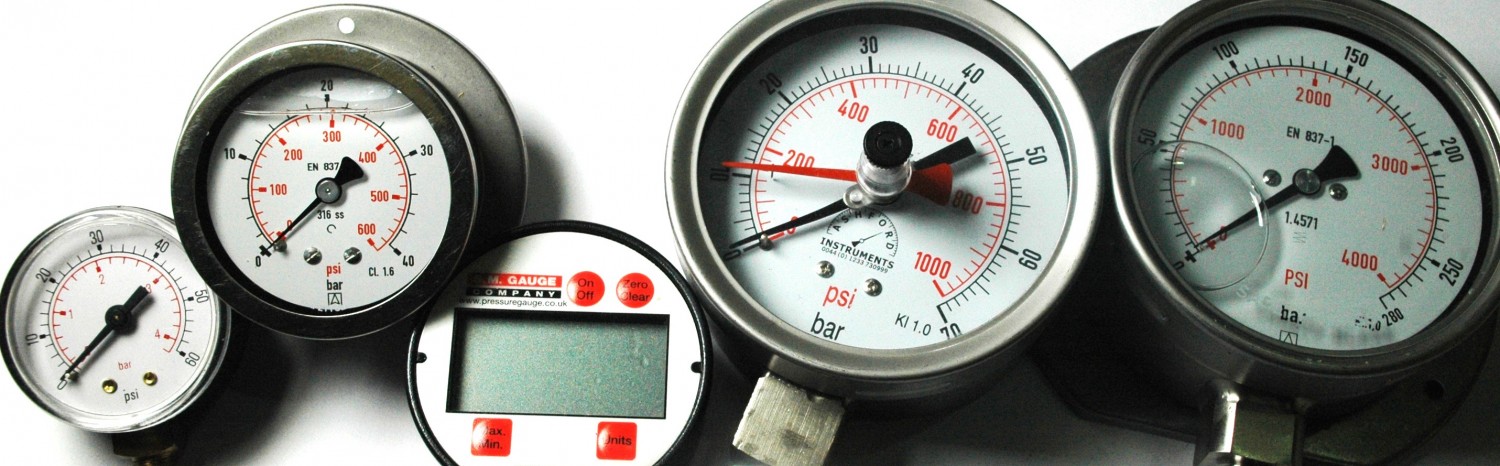

Pressure gauge range selection for hydrotest.

The pressure gauges should be calibrated within a year and the pressure range of gauge should not be less than 1 5 greater than 4 times the hydrotest pressure.

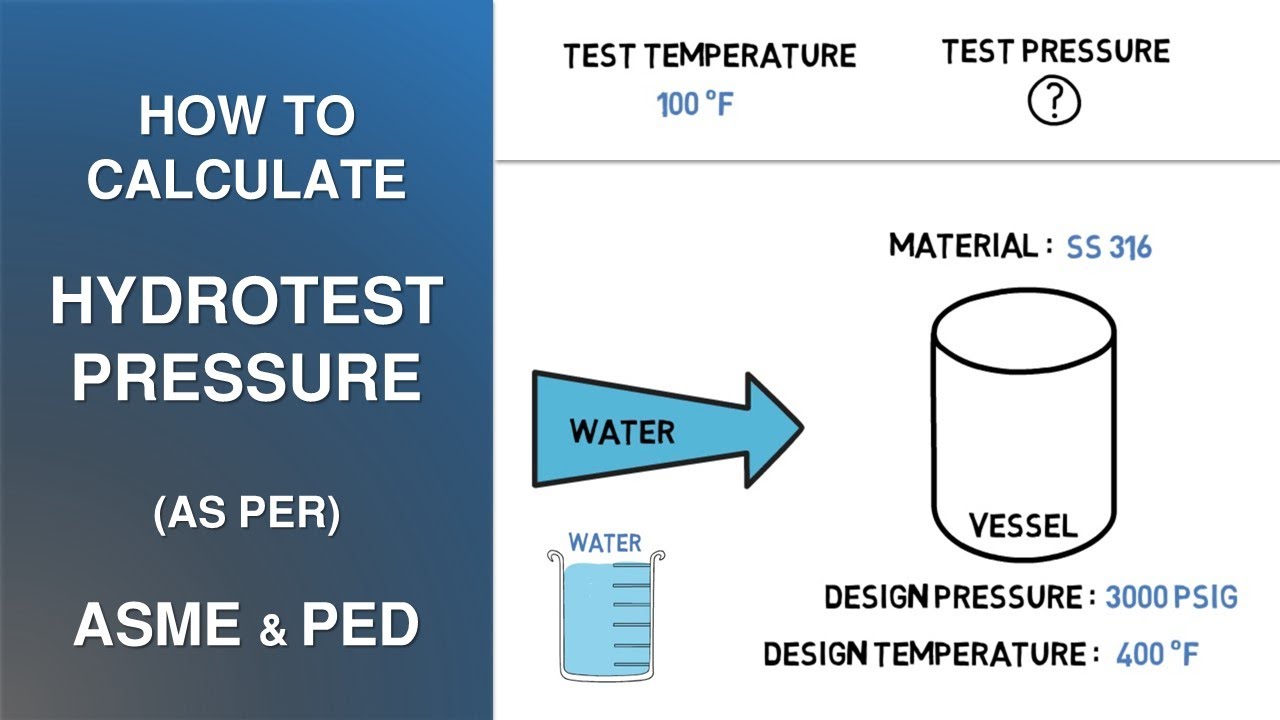

P t minimum test gauge pressure.

The size of the gauge is decided according to the client specification as per asme sec v t 1030 and sec viii div 1 ug 102 there is nothing given except the pressure range.

For a mechanical pressure gauge accuracy is defined either as a percentage of the full scale range or a percent of the span.

Normally a gauge used is 41 2.

Gauge accuracy pressure gauge accuracy ranges from grade 4a to d according to asme 40 1.

Shop hydrostatic testing of piping systems or.

2 water selection criteria for hydrotest.

Pressure gauge selection considerations in selecting a pressure gauge 4 range the maximum operating pressure should not exceed 75 of the full scale range.

Minimum accuracy should be 1 with minimum sensitivity of 0 5.

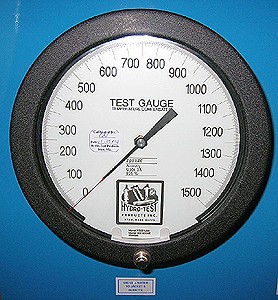

The 1 5x to 4x is the requirement for the range of the gauge relative to the calculated hydrotest pressure per asme viii.

Maximum test pressure but should not exceed 200.

To select the right pressure gauge for your application the following factors should be considered.

The 1 5x to 4x limits only applies to analog gauges and that s because they reach their best accuracy as a percentage of full scale within this range.

Range of the master test gauge should be greater than the.

Making sense of different ranges on hydraulic pressure gauges.

Indicate actual hydrostatic test pressures.

Selecting the right hydraulic pressure gauge for your hydraulic application.